Renewable Energy Manufacturing

Clarity that scales with precision

Clarity that scales with precision

Growth without reliability isn’t progress.

The renewable energy market is expanding fast, and so are its expectations.

Component and equipment manufacturers are under pressure to deliver more capacity, tighter timelines, and flawless traceability.

Your systems were designed for stability, not speed. Now they are straining to keep up with demand, compliance, and constant change.

The Challenge

Data lives in silos, quality records lag behind production, and manual steps create small inefficiencies that compound across operations.

You know there is potential to improve performance and control costs, but after years of system patches and partial upgrades, you are cautious.

You don’t need another digital transformation headline. You need evidence that each investment will create measurable impact.

The real problem isn’t growth. It’s uncertainty about where to focus first and how to prove the payoff.

Data lives in silos, quality records lag behind production, and manual steps create small inefficiencies that compound across operations.

You know there is potential to improve performance and control costs, but after years of system patches and partial upgrades, you are cautious.

You don’t need another digital transformation headline. You need evidence that each investment will create measurable impact.

The real problem isn’t growth. It’s uncertainty about where to focus first and how to prove the payoff.

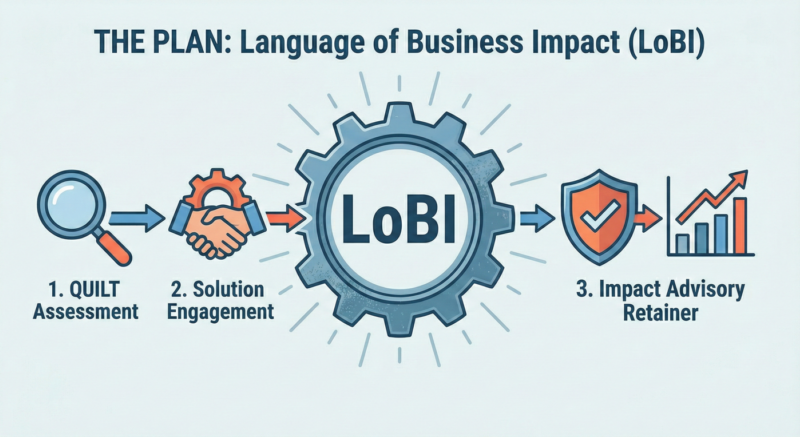

The Plan

Many renewable energy manufacturers face this same pressure.

The Language of Business Impact (LoBI) brings clarity and accountability to every technology decision.

We help you align operational systems, validate investments, and identify where improvements deliver measurable gains in reliability, performance, and EBITDA.

Clarity begins with evidence. Every engagement follows a focused, repeatable path that strengthens control and protects profitability.

- Start with a QUILT Assessment – Assess how well your production, compliance, and reporting systems work together. Identify integration gaps and risks that could limit scalability.

- Refine with a Solution Engagement – Quantify the financial and operational impact of system improvements and prioritize the initiatives that create measurable ROI.

- Sustain with an Impact Advisory Retainer – Maintain clarity as you grow, ensuring every new initiative supports both performance and profitability.

Every recommendation is based on measurable value. Every step is grounded in evidence before execution

Many renewable energy manufacturers face this same pressure.

The Language of Business Impact (LoBI) brings clarity and accountability to every technology decision.

We help you align operational systems, validate investments, and identify where improvements deliver measurable gains in reliability, performance, and EBITDA.

Clarity begins with evidence. Every engagement follows a focused, repeatable path that strengthens control and protects profitability.

- Start with a QUILT Assessment – Assess how well your production, compliance, and reporting systems work together. Identify integration gaps and risks that could limit scalability.

- Refine with a Solution Engagement – Quantify the financial and operational impact of system improvements and prioritize the initiatives that create measurable ROI.

- Sustain with an Impact Advisory Retainer – Maintain clarity as you grow, ensuring every new initiative supports both performance and profitability.

Every recommendation is based on measurable value. Every step is grounded in evidence before execution

The Victory

When your systems work together, reliability turns into strength.

Production stabilizes, compliance strengthens, and leadership gains confidence in every decision.

You can scale without losing control. That is what clarity delivers: growth that is both measurable and sustainable.

When your systems work together, reliability turns into strength.

Production stabilizes, compliance strengthens, and leadership gains confidence in every decision.

You can scale without losing control. That is what clarity delivers: growth that is both measurable and sustainable.

Success Story: American Roll Form Products (ARF)

The Client: American Roll Form Products (ARF), a custom metal fabricator, relied on multiple systems to manage operations, but their ERP, warehouse management, and plant-floor data rarely agreed. Reports told conflicting stories, forcing the team to make decisions with incomplete information. The Refinery helped ARF shift focus from building better reports to unifying the story their data was telling. We guided the development of a central reporting database that integrated all three systems and built forward-looking reports tied to specific business decisions.

The Result: The result was a single source of truth that reduced waste, improved margins, and gave leadership real visibility into job performance and resource utilization. What started as a reporting request became a foundation for how ARF manages performance and profitability across the organization.

Frequently Asked Questions

1. What makes your approach different from typical digital transformation consultants?

We don’t start by suggesting solutions. We start by identifying where value can be found. The LoBI framework brings financial discipline to technology decisions, ensuring every action taken has measurable impact and a clear business case.

2. How do I know if our systems are limiting our growth or scalability?

If production slowdowns, compliance issues, or data inconsistencies appear as you expand, your systems are signaling misalignment. The QUILT Assessment identifies the root causes and helps you prioritize the improvements with the highest return.

3. Can we improve reliability without rebuilding everything?

Yes. Most renewable manufacturers already have capable systems in place. The key is strengthening how they connect and communicate. We help you pinpoint where integration and process alignment will deliver the greatest impact with the least disruption.

4. How long before we see measurable improvements?

Within 60 days, most teams have already implemented at least one measurable improvement. Because our recommendations are prioritized and evidence-based, every decision you make ties directly to performance and financial results.

Start where clarity begins with the QUILT Assessment.

It is a low-risk, high-value diagnostic that helps renewable manufacturers gain control, confidence, and measurable ROI from the systems they already rely on.