Automotive Industry

Clarity that protects margin in a complex supply chain

Your margins live and die by precision.

You are part of the massive supply chain that feeds the automotive industry. Every component, every shipment, every delay has a ripple effect that can stall production or strain relationships. The pressure to modernize never stops, yet every technology decision carries real financial risk, and the cost of getting it wrong grows every day.

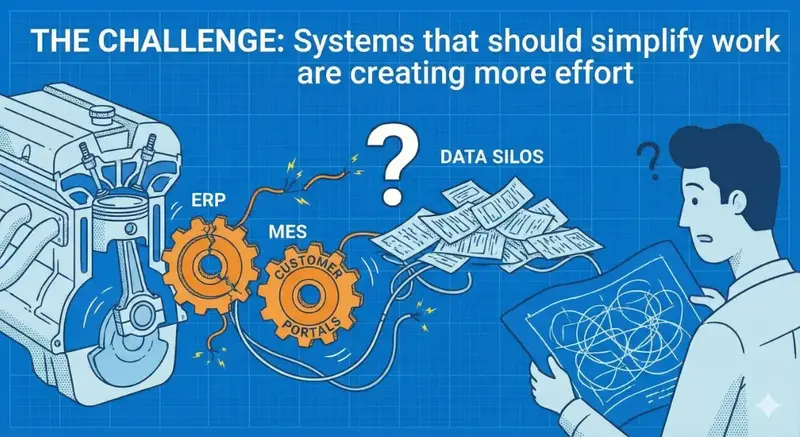

The Challenge

Systems that should simplify work are creating more effort. ERP, MES, and customer portals don’t always align, leading to data silos that slow decisions and hide inefficiencies. You know there’s opportunity to improve manufacturing efficiency, but after a few disappointing projects, you’re cautious. You don’t want another “modernization” effort that drains resources and leaves you wondering what changed.

The real problem isn’t effort or intention. It’s uncertainty about what to fix first, and how to prove it’s worth doing.

Systems that should simplify work are creating more effort. ERP, MES, and customer portals don’t always align, leading to data silos that slow decisions and hide inefficiencies. You know there’s opportunity to improve manufacturing efficiency, but after a few disappointing projects, you’re cautious. You don’t want another “modernization” effort that drains resources and leaves you wondering what changed.

The real problem isn’t effort or intention. It’s uncertainty about what to fix first, and how to prove it’s worth doing.

The Plan

Many automotive suppliers face this same tension. The Language of Business Impact (LoBI) brings structure and financial discipline to every technology decision. We help you see where restraint protects profit and prove where technology modernization truly improves performance and ROI.

Clarity begins with evidence. Every engagement follows the same simple path — a roadmap designed to reduce waste and strengthen manufacturing efficiency.

- Start with a QUILT Assessment – Evaluate how well your systems, data, and processes are stitched together to support operations. Identify ERP, MES, and reporting gaps that slow performance.

- Refine with a Solution Engagement – Quantify the business value of potential improvements and create a clear technology roadmap that identifies what’s truly worth doing.

- Sustain with an Impact Advisory Retainer – Keep clarity alive as your business scales and priorities evolve.

Every recommendation is based on measurable value. Every step is grounded in evidence before execution.

Many automotive suppliers face this same tension. The Language of Business Impact (LoBI) brings structure and financial discipline to every technology decision. We help you see where restraint protects profit and prove where technology modernization truly improves performance and ROI.

Clarity begins with evidence. Every engagement follows the same simple path — a roadmap designed to reduce waste and strengthen manufacturing efficiency.

- Start with a QUILT Assessment – Evaluate how well your systems, data, and processes are stitched together to support operations. Identify ERP, MES, and reporting gaps that slow performance.

- Refine with a Solution Engagement – Quantify the business value of potential improvements and create a clear technology roadmap that identifies what’s truly worth doing.

- Sustain with an Impact Advisory Retainer – Keep clarity alive as your business scales and priorities evolve.

Every recommendation is based on measurable value. Every step is grounded in evidence before execution.

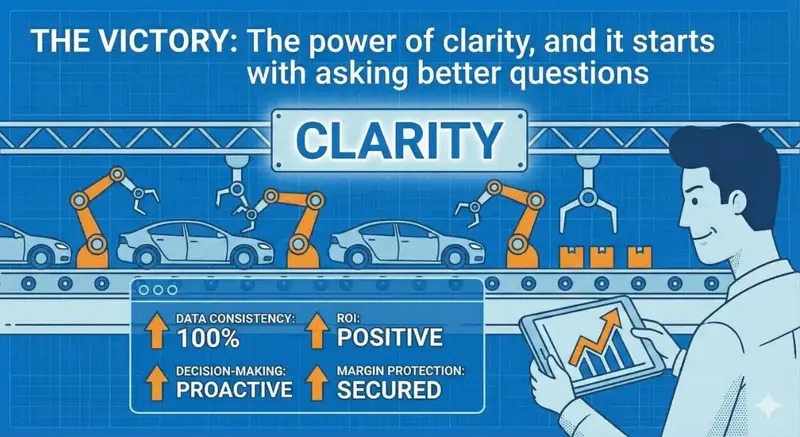

The Victory

When your data tells a consistent story, decision-making becomes simple. Your teams stop reacting and start anticipating. You see where to invest, where to wait, and how every move ties to margin protection and long-term ROI. That’s the power of clarity, and it starts with asking better questions before spending another dollar.

When your data tells a consistent story, decision-making becomes simple. Your teams stop reacting and start anticipating. You see where to invest, where to wait, and how every move ties to margin protection and long-term ROI. That’s the power of clarity, and it starts with asking better questions before spending another dollar.

Success Story: How Clarity Drove Measurable Impact

Client: Hawk Performance had earned deep loyalty among racers and enthusiasts, but an outdated website was undermining that reputation. Dropped carts, frustrated customers, and internal teams fighting their own systems just to manage thousands of SKUs were holding the brand back. The Refinery brought clarity before design, helping Hawk step back from their initial vision to rethink the full experience, from platform selection and catalog architecture to the end-to-end customer journey.

Result: The result was a faster, intuitive site where customers find the right parts with confidence, checkout is seamless, and Hawk's team manages their catalog without friction. Every decision was grounded in what would drive measurable improvement, and the new platform now reflects the precision of the brand it represents.

Frequently Asked Questions

1. What makes your approach different from a traditional IT consultant or integrator?

We don’t start by suggesting solutions. We start by proving value. The LoBI framework brings financial discipline to technology decisions.

2. How do I know if our ERP or MES system is holding us back?

If your team spends hours reconciling data between ERP and MES, that’s hidden waste, and lost profit. The QUILT Assessment identifies where these gaps exist and shows whether integration or process refinement will deliver the best return.

3. We’ve already invested heavily in technology. Can you work within what we have?

Absolutely. Most automotive suppliers have significant legacy systems in place. We focus on strengthening what you already own, not replacing it. The goal is measurable improvement with minimal waste.

4. How long does it take to see value after an assessment?

Many suppliers begin implementing high-impact changes within weeks. Because our recommendations are quantified and prioritized, every decision you make is tied to real financial outcomes.

Every action taken has measurable impact and a clear business case.

Start where clarity begins: with the QUILT Assessment. It’s a low-risk, high-value diagnostic that gives automotive suppliers a clear view of how their systems, data, and operations align to improve performance and ROI.