From CAD to Finished Product: The Manufacturing Process of Medical Devices

The manufacturing of medical devices has advanced significantly thanks to the latest manufacturing techniques. In this blog post, we will explore the manufacturing process of medical devices, from Computer-Aided Design (CAD) to the finished product, and highlight how advanced manufacturing is shaping the industry.

Medical devices are critical tools used to diagnose, treat, or prevent diseases or other medical conditions. Examples include surgical instruments, diagnostic equipment, pacemakers, and prosthetics. These devices are manufactured with utmost precision and quality, meeting strict regulatory standards such as FDA approval.

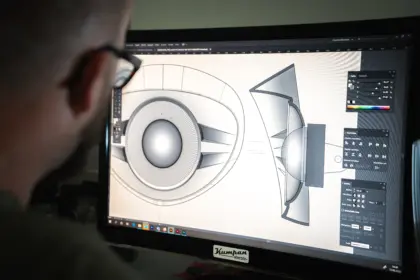

The first stage of manufacturing medical devices is the design process using CAD software. The CAD model can be refined, modified, and reviewed until it meets the specifications. This process ensures the design is perfected before the manufacturing phase.

The next step is prototyping, where physical models of the device are made for testing. Various manufacturing techniques are employed in the prototyping stage, including CNC machining, injection molding, or 3D printing.

Techniques like CNC machining involve precise computer-controlled machines that accurately remove materials to create the device's desired shape. Injection molding is also common in medical device production, involving injecting molten material into a mold to create the device's specific shape. On the other hand, 3D printing builds objects layer by layer and is commonly used to create complex shapes or structures quickly and at a lower cost.

The next stage is production, where the device is manufactured using the chosen technique. The device is then rigorously tested to ensure it meets safety and efficacy standards. Laboratory testing and clinical trials are conducted, and once the device passes all necessary tests and trials, regulatory bodies approve it. The device can then be marketed and sold to hospitals, clinics, and other medical facilities.

Advanced manufacturing techniques such as CAD, CNC machining, injection molding, and 3D printing have revolutionized the manufacturing of medical devices. The devices' precision and complexity are a result of these techniques, enabling manufacturers to produce highly functional and reliable medical devices that meet regulatory standards. Advanced manufacturing is shaping the future of medical devices and driving innovation in the healthcare industry.